EN/CNC made seal: Unterschied zwischen den Versionen

Stp (Diskussion | Beiträge) K |

Stp (Diskussion | Beiträge) K |

||

| Zeile 32: | Zeile 32: | ||

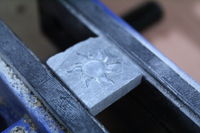

[[Datei:IMG_4227.JPG|thumb|left|200px]] | [[Datei:IMG_4227.JPG|thumb|left|200px]] | ||

| + | {{clear}} | ||

== Postproduction == | == Postproduction == | ||

| Zeile 41: | Zeile 42: | ||

test sealing wax | test sealing wax | ||

too deeply engraved -> sealing wax stuck | too deeply engraved -> sealing wax stuck | ||

| + | |||

| + | {{clear}} | ||

| + | |||

[[Datei:IMG_4231.JPG|thumb|left|200px|Filled with hard sealing]] | [[Datei:IMG_4231.JPG|thumb|left|200px|Filled with hard sealing]] | ||

got stuck | got stuck | ||

| + | |||

| + | {{clear}} | ||

| + | |||

[[Datei:IMG_4235.JPG|thumb|left|200px|Sanded down into amulet shape]] | [[Datei:IMG_4235.JPG|thumb|left|200px|Sanded down into amulet shape]] | ||

grinding down into amulet form | grinding down into amulet form | ||

Version vom 25. Februar 2016, 14:05 Uhr

| CNC Made Seal (en) Status: unstable | |

|---|---|

| |

| Beschreibung | Delicate milling |

| Autor: | stp |

| Version | 0.1 |

| PayPal | |

Description

As raw material we use soapstone. Our soapstone specifically sourced and is free from asbestos. The main machine used for engraving the signet our CNC machine. We engrave a unique emblem or logo into a prepared piece of soapstone. Soapstone is used due to its soft material, which is great for CNC usage, and its resistance to heat, water and sealing wax. This is especially needed during the sealing process involving higher temperatures.

Preparation

As a preparatory step we split the bigger soapstone blocks into small plates, which are easier to handle and mount within the CNC machine. The soapstone is basically cut from the source material with a wood saw. Rough and uneven edges are grinded and straightened to make handling and mounting easier afterwards.

Milling

Postproduction

Failure - Amulet

test sealing wax too deeply engraved -> sealing wax stuck

got stuck

grinding down into amulet form made amulet out of it