EN/Aluminumcasting: Unterschied zwischen den Versionen

K (Schinken verschob Seite Aluminiumguss (en) nach Aluminumcasting en: better name) |

|||

| Zeile 9: | Zeile 9: | ||

|visible = false | |visible = false | ||

}} | }} | ||

| + | |||

| + | __TOC__ | ||

[[Category:Hardware]] | [[Category:Hardware]] | ||

[[Kategorie:howto]] | [[Kategorie:howto]] | ||

| + | |||

| + | {{Ambox|text=This Article is also available in [[Aluminiumgiessen|German]]}} | ||

== Preface == | == Preface == | ||

Version vom 20. November 2012, 13:40 Uhr

| Aluminiumguss Status: stable | |

|---|---|

| |

| Beschreibung | the art of making aluminum out of styrofoam. |

| Autor: | ptflea |

| Version | 0.8 |

| PayPal | |

| This Article is also available in German |

Preface

This is just a report of what we did. Please be careful when trying to do what we have done! Use your brain!

Questions about the project can be sent to ptflea [at] hackerspace-bamberg [dot] de

After successfully getting the styroplotter to work, it was time to cast some aluminum. Aluminum has the advantage of melting at a low temperature, making it possible to use a simple propane flame.

Materials

- aluminum

- a styroplotter

- styrofoam

- Ytong bricks

- silica sand

- propane gas with burner

- melting pot

- face protection

- no plastic clothing or short pants

- caution! It is very, very hot material with which you won't want to get in contact!

- bucket of water to cool off the hot aluminum

- old pots and bowls

- pipe wrench and old screw drivers

Furnace

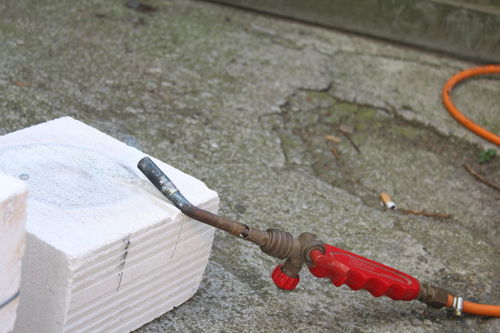

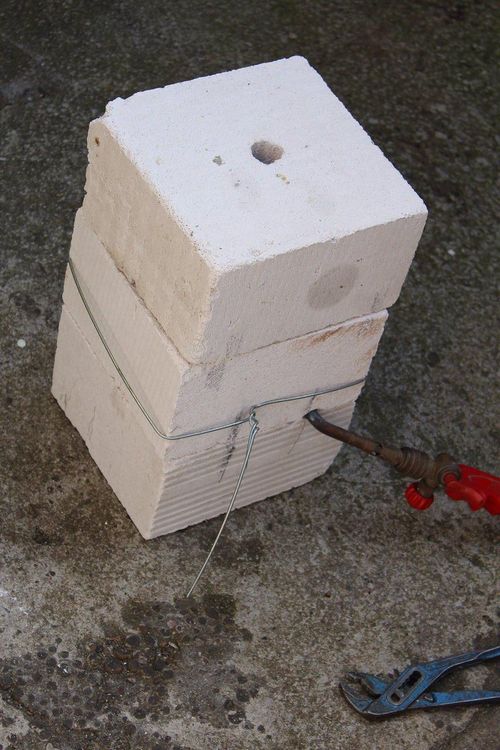

Saw the Ytong brick into three 20x20 parts and pierce one in the middle for the melting pot to fit in. Put the burner into the lower brick and scrap an air conduct next to it. Make a hole for exhaustion and perhaps two flow-out channels.

Even for an Ytong brick the heat can be too much and it will break, that's why we put wire around it.

Aluminum

The basic material consists of processor cooling elements.

We made them fit with a hammer.

The styro parts have to be glued together and a filling piece attached.

Preparation

The styro parts are completely immerged into the sand.

Aluminum cast

Get the burner burning and don't leave it alone.

When the aluminum has melted, and take the slag off with a screw driver.

Cast now!

VIDEO: https://vimeo.com/42302000

VIDEO: https://vimeo.com/42464520

VIDEO: https://vimeo.com/42464519

Fetch the casted material from the sand, using the wrench. Remember that it can still be very hot!

Cool it in the water bucket.

VIDEO: https://vimeo.com/42464521

Postproduction

Saw off the filling piece!